Do You Have Your CARB Prebuy Allocation Plan Ready?

With the growing awareness of the California Air Resources Board (CARB) mandates and plans, one major question looms over organizations with transportation fleets: how will this ruling truly impact their procurement cycle? Last year the U.S. Environmental Protection Agency (EPA) gave its approval to California's plans, which call for an increasing number of zero-emission heavy-duty trucks. This move lines up with the state's commitment to reducing pollution as enforced by CARB, which aims for electric trucks to make up half of all heavy-duty truck sales in the state by 2035.

CARB Mandates Will Cause A Spike In Prebuy Activity

Vehicles with differing types and usages will have various phase-in dates according to the CARB plan. As such, state and local governments would be required to obtain zero-emission vehicles amounting to 50% of the additions to their fleets beginning in 2024. All new purchases would have to be ZEVs beginning in 2027.

According to ACT Research and Fleet Advantage research, there will be a significant prebuy of Class 8 trucks before the EPA upcoming round of emissions regulations targeting diesel exhaust emissions in 2027. ACT analysts believe the new standards will result in the largest truck prebuy ever, beginning in 2025 into 2026. Why all the talk of prebuys? These new mandates will further drive up the cost of diesel trucks to the tune of $25,000 - $30,000 extra per unit. This is in addition to the already rising baseline equipment cost.

Fleets Taking A Reactionary Approach Will Suffer

Companies understand the importance of transitioning to a greener footprint. The problem most fleets may run into is taking a reactionary approach to their procurement cycle in trying to join in on the prebuy cycles – which will further create problems in the supply chain of truck availability.

So, what are some of the leading transportation fleets in the country doing to prepare? Start preparing now with these action items!

- Establish a multi-year procurement plan: Fleets today are inundated with data. Most fleets have maintenance software systems that will provide every repair and every line item. They also have ELD devices and onboard computers that tell you where you've gone, how many miles you've run, how heavy you were when you ran those miles, and what part of the country you were in. However, companies need help today taking all that data and saying, what is the offering from the OEM? What is out there in the marketplace? What is the data that we've collected telling us? And how do we put that into a roadmap for the next one, three, and five years?

- Utilize actionable data and procurement planning: Having insight into and understanding your data is crucial to building fleet modernization studies that scrutinize performance data, life cycles and economic factors to determine an optimum procurement strategy

- Build a fleet modernization plan: Work with your asset management partner to identify a holistic approach that leverages your actual data, which will also help you lower your bottom-line costs over time

- Identify your fleet’s life cycle and requirements: It’s important to leverage utilization data to identify what percentage of electric is going to fit (if any) into your fleet

- Build your ESG roadmap: Fleets need to bridge today’s clean-diesel technology into tomorrow’s alternate fuel options. An ESG roadmap will help determine which truck procurement strategy works for your organization and will maximize environmental considerations

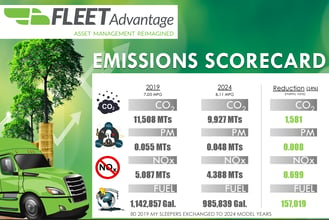

- Utilize emissions scorecards: Data is being used in emissions scorecards to evaluate and reduce a fleet’s carbon footprint. The study reviews the entire fleet by year, make, model, and compares fuel and mileage data and provides detailed information on CO2 reduction in metric tons and gallons of fuel saved, each time the truck was replaced

By implementing these strategies to prepare, fleets can optimize their environmental impact and seamlessly transition towards alternative fuel technology. In doing so, they will successfully attain crucial ESG goals while operating the most suitable equipment for their specific operations.

The fleets that operate with the lowest cost of ownership are the ones that subscribe to this flexible and environmentally responsible procurement strategy. As a result, forward thinking fleets can avoid the need to react to prebuy cycles by partnering with strategic asset management partners and using actionable data. By doing so, they can focus on their operations and achieve a lower total cost of ownership, while gradually transitioning to emission-free trucks.

.jpg)